Nail Components (Pt 1)

We've talked a lot about using nail guns, but what about the nails that go in them? We get questions all of the time asking about the components of a nail. The type? The shank? Point and finish?

The average person only knows about one type of nail; the simple flat head design with a smooth shank and blunt diamond point. This is the most common style for nails used in everyday construction, but what about other nail types? Let's take a look at some of the variations in nail design and function - but first, let's go over some basic terms that define the structure of a nail.

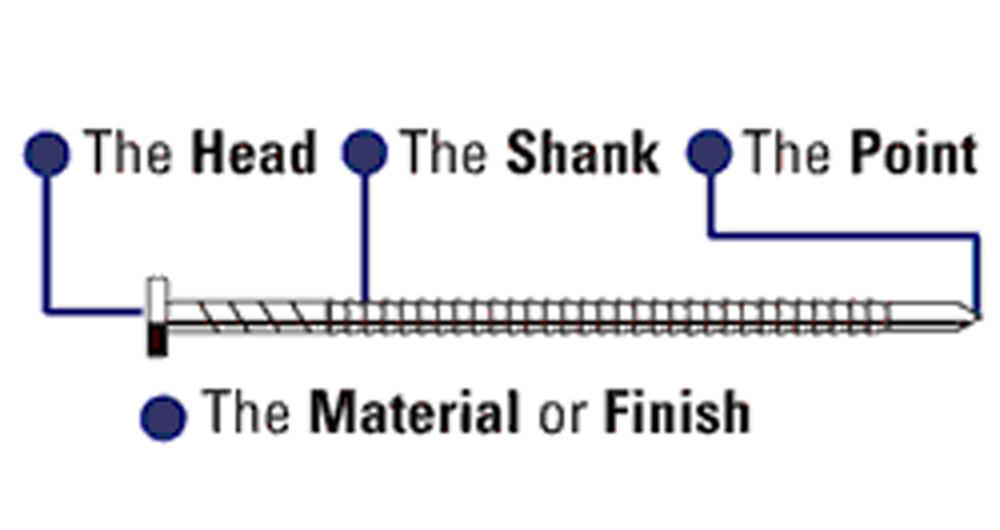

A nail is composed of three parts: head (top), shank (body) and point (tip). Size and length will vary depending on the type of job you are working on - your nail gun will tell you which size nails it will work with. Finally, you have the finish of the nail, which represents the nail's exterior - and can come coated (resin), galvanized (dipped) or untreated.

Now that we know some of the basic terms regarding the structure of a nail, it's time to look at the variations in their structure.

Nail Head Types

Flathead Nail - This is the most common type of head for a nail. Available in different forms such as full (regular), clipped (reduced head size) and off center (head sits to the side of base), this nail's larger head size offers stronger holding capability.

Brad & Finish Nails - These nails are typically used for finishing work, such as attaching trim and molding. Having a smaller head means these nails do not have the holding strength of their flathead counterpart, but they are able to fit in tighter places and are less noticeable to the naked eye, after installation.

Duplex Nail - The duplex nail is intended for temporary use, featuring a double head for easy removal. These nails resemble a push-pin, and are designed to work as a placeholder - before a permanent application has been made.

Nail Shank Types

Smooth Shank Nail - The smooth shank is the most common shank that can be found on nails. The easiest to produce, this type of shank also provides the least amount of holding strength.

Ring Shank Nail - The ring design on a shank provides improved holding strength and can be recognized by the threaded rings that run along the body of the nail. Its appearance resembles a smooth body nail running through a spring.

Screw Shank Nail - A screw design has a body similar to its screw counterpart, but is driven into wood without the traditional screw head. It features a spiral design that covers about 3/4 of the nail's body.

Spiral Shank Nail - Similar to the screw, this shank spirals the entire body of the nail.

Nail Point Types

Blunt Point- This is the most common of nail points. It reduces splitting when being driven, which makes it an asset to anyone using a nailer.

Long Point - This point is mostly used in drywall installation, as it has a long, sharp, needle-like tip that can be driven deep.

Chisel Point - This type of point is mostly used for heavy duty projects, such as pallet-building and industrial assembly. The chisel tip also helps to avoid splitting.

Flat point - This point does not have a sharp or jagged edge. It features a smooth point.

Clinch Point - This point is off center, but is sharp like the chisel. One side of this point is shorter than the other.

Check back next week for the second half of this two-part series on nail components!

Best Of Luck On Your Next Project,

~ The Nail Gun Depot Team