First Look: Senco Introduces Composite Tool & Fastener Line

Senco is taking a big step into uncharted territory, as the company launches its full line of plastic composite finish nails and staples, as well as the tools to run these composite fasteners. A completely new concept for a brand recognized for its steel nails and staples, Senco composite fasteners are 100 percent metal-free, formed from a blend of polymer resin and fiberglass. And, while these collated plastic fasteners may sound secondary compared to their steel and metal counterparts, the reality is quite opposite.

The plastic polymer base for Senco composite fasteners allows these nails and staples to do some pretty neat things - things your average metal fastener can't do. These composite fasteners can be sanded, shaped, and cut without damage to router bits, cutting blades or sanding belts. Senco also claims they offer "superior holding power, excellent processing characteristics, and long-term resistance to chemicals, sunlight, and moisture." A major advantage we see at first look, no rust, corrosion or staining with these plastic nails and staples.

But what about durability and strength?

According to Senco, their composite finish nails hold up to two-times stronger than similar sized steel nails, BUT Senco also notes adhesives will do the heavy lifting after curing. Our take, these fasteners - particularly the composite finish and brad nails - are ideal for holding materials in place while adhesives cure. Even better, the non-metal material can be sanded or cut once the adhesive has completely set; meaning you can either leave them in place without fear of corrosion, or sand them down without damaging your tool.

Other benefits these Senco plastic composite fasteners offer, no clamping set up time or waiting, they eliminate the drudgery of removing problematic fasteners and marring wood surfaces, have zero adverse affect on final product appearance and performance, all while reducing wear on sanding and cutting equipment.

So what exactly are composite fasteners good for?

These plastic fasteners are designed for more than meets the eye. As mentioned before, composite finish nails and staples are perfect for use with woodworking adhesives, to provide a temporary hold until the adhesive cures. Professionals and hobbyists alike benefit from the ability of the fastener to be sanded, shaped and cut. Senco 15-gauge and 18-gauge composite finish nails are also ideal for use with CNC machines for cutting, carving, drilling and machining a variety of materials without damaging router bits and saw blades. Multiple pieces of material can be stacked and attached to the spoil board with composite fasteners, to increase production output.

Senco 15 gauge composite finish nails are perfect for use with Cellular PVC adhesives, to provide a temporary hold until the adhesive cures. Industrial fabricators benefit from the use of composite nails in the production of pergolas, arbors, trellises, custom columns, flower boxes, vents, window trim, copulas and laminations.

You may also find these composite fasteners ideal for lumber tagging. Composite fasteners will not degrade in sunlight, high heat conditions, or cause interference in microwave and RF environments - assuring a long-term, problem-free tagged product.

What tool do you need, to use a Senco composite fastener?

Along with the plastic composite nails and staples, Senco released seven tools, each designed to run collated composite fasteners exclusively. A finish nailer, brad nailer, hammer tacker, squeeze stapler, two 16 gauge air staplers, and a 20 gauge pneumatic stapler to be precise. Remember, you CAN NOT use a regular nailer or stapler for these plastic composite fasteners - the driving power is too strong.

We'll go in-depth with these composite fastening tools in a later post, but for now, here's a list with links below:

- SPFN15XP 15 Gauge Composite Finish Nailer (9H0001N)

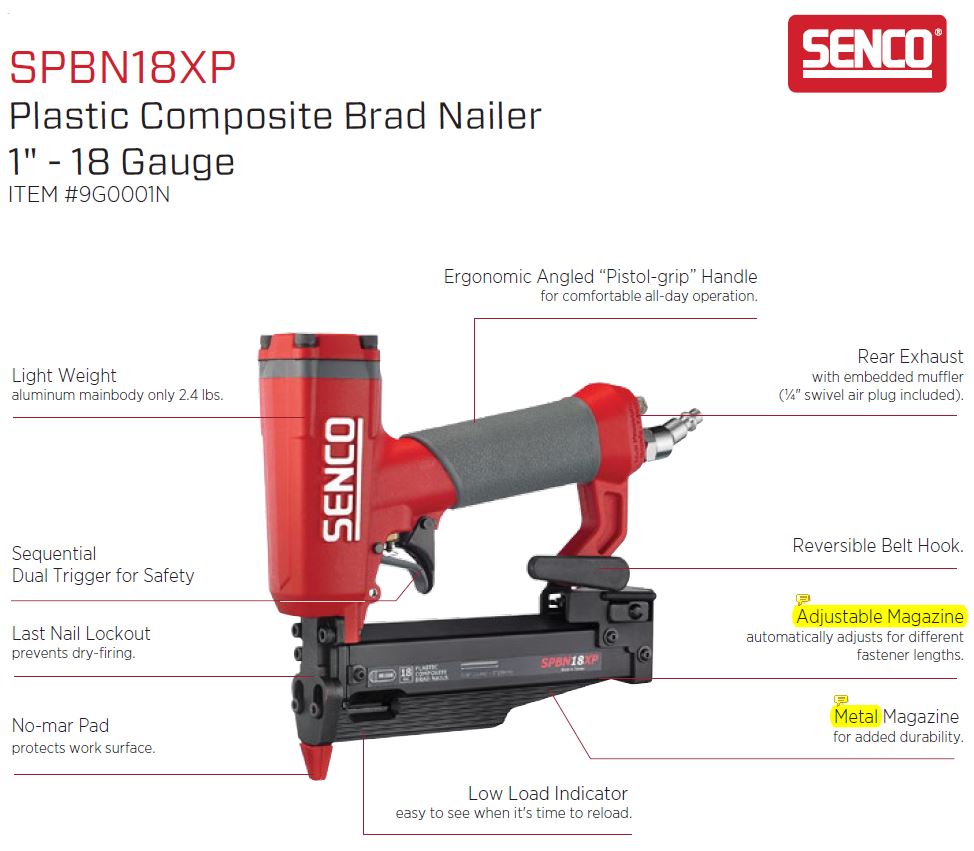

- SPBN18XP 18 Gauge Composite Brad Nailer (9G0001N)

- SPHT Composite Hammer Tacker (9M0001N)

- SPCT 20 Gauge Manual Squeeze Composite Stapler (9N0001N)

- SPS16XP-11 16 Gauge Composite Stapler (9J0001N)

- SPS16XP-12 16 Gauge Composite Stapler (9K0001N)

- SPS20XP-12 20 Gauge Composite Stapler (9L0001N)

Will plastic composite fasteners be the next new thing?

The verdict: too soon to tell. Several competing products from brands such as RAPTOR® and OMER have been available for a while. However, these new Senco composite fasteners may hold two huge advantages over existing composite fastening products. Number one, the name. Senco is a household name in fastening. Adding Senco branding to these products may make the difference, as they make their mainstream debut. Woodworkers and fabricators who have never heard about composite fasteners will suddenly have a plethora of knowledge at their fingertips, as word spreads throughout the fastening industry. Number two, quality. If Senco composite fasteners can withstand the test of time, we should expect to see them around for the long haul.

To reiterate key features and benefits for Senco composite fasteners:

- 100% steel and metal free

- Flash bonds with wood fibers

- Eliminate clamping tools and screws

- Reduce curing time workability

- No need to remove

- No need to repair imperfections

- Sanding belt safe

- Router bit safe

- No rust or corrosion

- Can be painted and stained

At first glance, Senco composite fasteners look to fill a big gap in the collated fastening marketplace. Would we recommend them, you bet.

~ The Nail Gun Depot Team

Thank you, Karen Argo/CCMHA Production Purchasing Clerk.

The F/15-125 CP composite fasteners are the same as the F15-32. You can <a href="https://www.nailgundepot.com/f15-32-114-leg-15-gauge-plastic-composite-finish-nail" rel="nofollow">click here to view more information including packaging quantity and pricing</a>.

For more info, you may also want to <a href="https://www.nailgundepot.com/contactus.asp" rel="nofollow">contact customer service</a> as well. Thanks!

I think you need to get this info into Fine Homebuilding and Fine Woodworking magazines

It's our opinion that these fasteners should primarily be considered for use in temporary applications, where they are used for temporary bonding - such as holding trim in place while wood glue is setting. The adhesive is intended to do the heavy lifting, not the plastic fastener.

For permanent use, especially in outdoor environments, stainless steel is still the best option.

This is mainly to make wood pallets for storage. Kindly send me a quotation for both the nail guns and the nails since both are not available in Uganda. Do you have any sub dealers of your products in Africa? Thank you.

Thanks for the message. We do not have any dealers internationally, unfortunately.

Please send an inquiry to <a href="mailto:sales@nailgundepot.com" rel="nofollow">sales@nailgundepot.com</a> and a customer service specialist can help figure out your situation. For international orders, we typically only accept wire transfer if credit card is not suitable.

It's the original, premium product... us & international.