Choosing a Laser Level: Red vs. Green Beam

If you work in any form of construction, electrical installation, heating and air conditioning installation, even laying tile, you undoubtedly understand the importance of using a laser level on the job site. But, have you noticed the steady transition from red to green laser beams?

The fact is, green is simply easier to see, but naturally, there’s more to it than that, so let’s have a closer look. Manufacturers, such as the German brand Stabila, have been utilizing green laser technology for a while now. Always innovative, the company uses "Green Beam" technology to enhance the quality of their lasers, as with the LAX50G cross line laser. The tool provides a 30m measuring range, and razor sharp, bright green lines — that are four times brighter than conventional red laser beams.

So, should you go green or opt instead for red? That depends on several factors, like working conditions, distance requirements and budget.

Getting The Facts Straight

You may recall from high-school science class that wavelengths for visible light range approximately from 400 nanometers to 700 nanometers (nm). Visible red light possesses the longest wavelength (about 625 to 740nm), violet is at the other end (380 to 435nm) and green lies right in the middle of the color spectrum at 532 nanometers. Not only is green the easiest color to see, it’s easier to see over a distance, which is important when using a laser level.

So why are most laser beams red?

Lasers work using diodes, and in the case of the red diode, they’re simpler to make, more readily available and cheaper than green diodes. When comparing the same laser product, the green laser option has historically been about 25% more expensive than its red counterpart.

Another downside of green lasers, their diodes use more energy. Because they have a higher output, battery life is depleted within a shorter time span. In the first iterations of green lasers, a red diode was actually used, and changed to green light through color conversion. Needless to say, it was an inefficient process.

Green Beam Technology

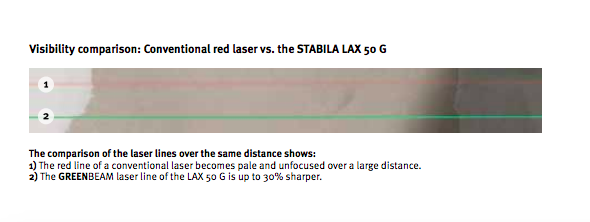

Manufacturers have since improved the technology behind green lasers, to increase battery life and monitor laser temperature. One result is Green Beam technology, which emits a fine green laser line that is four times brighter — and 30% sharper — than a conventional red line laser.

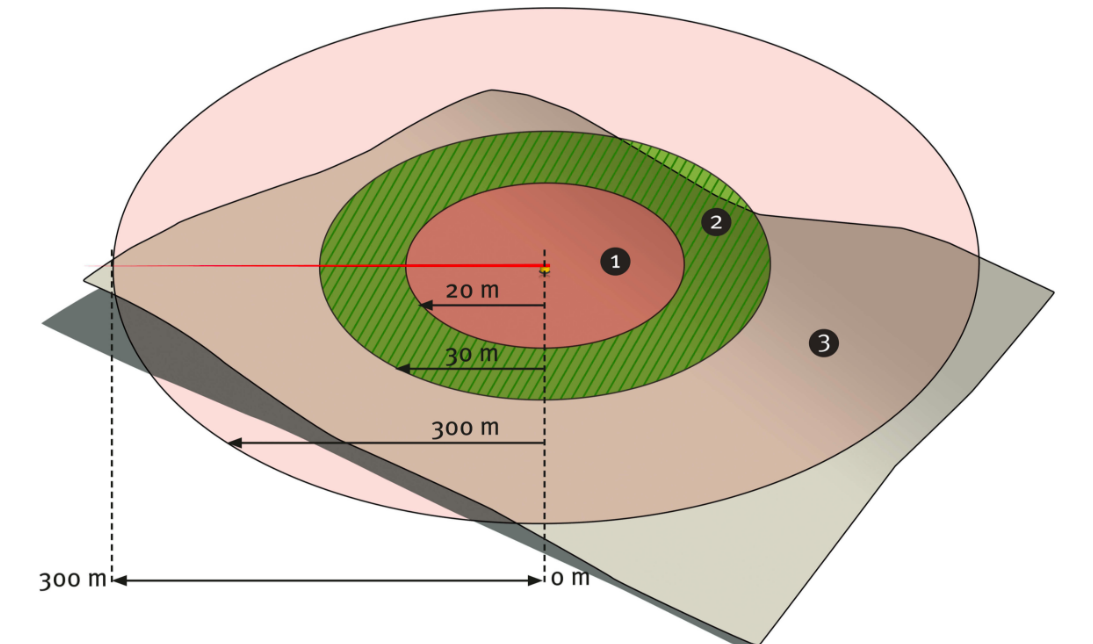

Compare these specs for the same tool with a different color laser; the Stabila LAX300 (red beam) and LAX300G (green). For the original LAX300, the battery run time is 20 hours with a visible measuring range of 20m (65’). For the 300G, the battery run time is 15 hours, but with a longer visible measuring range of 30m (98’). The main difference in the two, of course, is the brightness.

When To Go Green

Knowing how effective Green Beam lasers are, why would you choose a red laser? Stabila helps answer this question with the following distance diagram.

Essentially, if you’re budget-focused and working mainly indoors (within a range of 66'), a red beam laser is sufficient. For outside work, or when longer range is required (within a distance up to 98’), a green laser is the optimal choice.

The bright light of the sun can wash out red laser light, so if you plan to work outdoors with a laser level, keep that in mind. Another point to consider, as distance increases, accuracy decreases. For long distance use, Stabila suggests using a laser receiver.

We say, if you’re looking for an easier-to-see, crisper laser line, go green. Even if the initial cost is a little greater with a Green Beam laser level, it will pay off in the work with clearer lines, greater ease of use and convenience. Not to mention less squinting.

~ The Nail Gun Depot Team