Within Reach: The Quik Stik Rafter and Truss Fastening System

For contractors who fasten rafter and truss-to-top plate connections, falling is a potential safety hazard. The Quik Stik Rafter and Truss Fastening System from Simpson Strong-Tie resolves some of issues associated with overhead fastening, making it safer and simpler to get the job done without the need for a ladder.

How Does the Quik Stik Work?

The Quik Stik System is a screw driving extension tool that attaches to a drill or driver with a minimum 1,200 RPM−including cordless screw drivers. To use the tool, insert the Quik Stik’s hex-drive shaft into the drill or driver motor’s chuck. Then push down on the head of the tool to expose the magnetic bit holder, and insert the T30 driver bit until it clicks. Ensure everything’s properly connected by doing an installation motion, sliding the drive shaft though the guide sleeve while running the motor. When you're all set, insert the compatible Strong-Drive SDWC truss screw into the head and you’re ready to go.

Like many of the screw driving systems from Simpson Strong-Tie, the Quik Stik makes the fastening process considerably faster and more convenient. With this particular innovation, Simpson Strong-Tie asserts the Quik Stik is essentially "eliminating the need for ladders, power nailers and compressor lines.” It's certainly a step up for those who do a lot of overhead fastening.

The rafter and truss fastening system has been evaluated and approved for five different types of installations: offset from stud (underside of top-plate, bottom edge of top-plate), wide face of stud, narrow face of stud, and front corner of stud (compound angle). Click here to see more specifics about Quik Stik approved installations.

Safety Improvements with the Tool

One of the most obvious issues with rafter and truss applications is the reach factor. You’ll likely need a ladder to fasten those connections, and with that comes with risk of falling. This tool provides a minimum of 43” extension for screw driving, so for most wall heights, you can forgo the ladder. If you use a cordless screw driver with the Quik Stik, you don't have the hassle of a cord, giving you greater freedom and mobility.

Another benefit of the tool is that, since you can work from the interior of a structure, you won’t have to lug a ladder outdoors—or have to contend as much with the elements. So there's less potential for slipping, tripping and dropping.

Also, you don’t have the heft of a pneumatic tool, thanks to the extension tool’s weight. Not including the motor you choose, the tool weighs about 6 lbs. This means less strain from lifting a tool overhead, which could lead to inaccuracies in fastener placement. The Quik Stik has a comfortable, rubberized grip; it’s really a well thought-out solution for driving screws overhead.

Unique Features on the Quik Stik

You’ll notice the special positioning prongs on the head of the tool, which is over-molded with nylon. The prongs help securely grip the top plate while driving screws. The manufacturer has also included a bubble level that can be positioned along the handle or tool's head. The level may be angled, and even removed.

On the head of the tool, there are bright-orange guidelines to help direct the screw to the optimal angle for truss and top-plate to rafter connections. An orange centerline guide on the Quik Stik's head is useful for locating 90-degree angles in vertical connections. Rocker arms on the head let you adjust for precision fastening.

When you pull back on the tool's head, this exposes the screw, letting you see exactly where you're going and preventing mis-installation. And, should you need to remove a screw, set the driver motor to reverse and just unscrew the fastener.

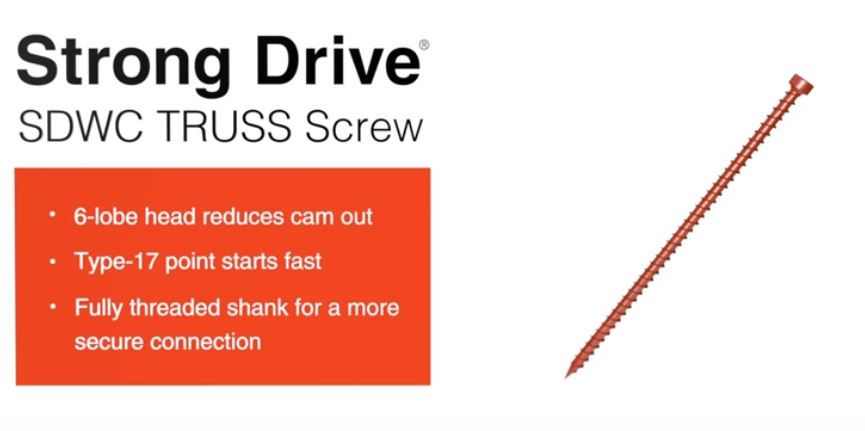

Quik Stik's Compatible Fastener

As mentioned, the Quik Stik drives the specially designed Strong-Drive SDWC truss screw. The 6” screw is fully threaded, engaging the entire length of the fastener. A cap-head on the screw allows it to be countersunk into double top plates. The SDWC screw also has a type-17 point for easier starting and driving.

The screws are code-listed under IAPMO –UES ER-262 and are tested in accordance with ICC-ES AC233 and AC13 for wall assembly and roof-to-wall assembly. With a bright-orange coating, the truss screw is easily visible and has a wide “tolerance” on angle installations, making it easy to install in a variety of positions.

Those familiar with the Quik Drive auto-feed systems from Simpson Strong-Tie will be curious about fastener collation. The Quik Stik system drives one screw at a time, so you won't be able to use collated screws. But who knows; perhaps Simpson Strong-Tie has already considered a solution for that, too.

Quik Stik Fast Facts

- Applications: Rafter Assembly/Truss-to-Top-Plate Connections

- Approved Installations: Offset from stud (Underside of Top-plate, Bottom edge of top-plate), Wide face of stud, Narrow face of stud, Front corner of stud (compound angle)

- Fasteners: Strong-Drive SDWC Truss Screws

- Screw Driver/Drill Motor: 1,200 RPM or Greater

- Driver Bit: T30 6-Lobe

- Attachment Weight: 6 lbs.

- Driver Bit Included: Yes

Are you ready to reach higher with the Quik Stik Rafter and Truss Fastening System? We’re certainly up to the task.

Shop Nail Gun Depot: